Business Area

KTG manufactures core electronic materials for digital displays.

Business AreaOverview of Photo Mask

- If you closely observe the screen of a TV, monitor, or mobile phone, you'll notice intricate circuits drawn in fine detail. These complex microcircuits are found on the display panel, and the photo mask plays a crucial role in helping to form these circuits.

- A photo mask is an etched pattern of microcircuits on a synthetic quartz base. When the photo mask is placed on the substrate where the microcircuits are to be drawn, light is passed through it. Light transmission varies depending on the etched areas of the photo mask, and the circuit is then transferred onto the substrate.

-

The ability of the photo mask to form fine patterns determines the quality and integration of semiconductors. In display devices, it must be used over large areas without distortion, making it a crucial raw material and a technological benchmark.

- KTG polishes synthetic quartz glass substrates, the primary material for photo masks. The main demand is for display devices such as TFT-LCD, Color Filters, and OLED panels. While photo mask substrates have traditionally depended on Japan, KTG has become a leader in the independent production of quartz transparent substrates, contributing to import substitution and improving pricing competitiveness.

Business AreaSynthetic Quartz Glass

- As the name suggests, quartz glass is a type of glass, but unlike other glasses made of various components, quartz glass is composed almost entirely of SiO2. The amount of metal impurities in quartz glass is meager, typically no more than a few tens of PPM (one in a hundred thousand), and in some cases, it is even less than 10 PPB (one in a hundred million). The very high purity of quartz glass gives it exceptional characteristics not found in other types of glass.

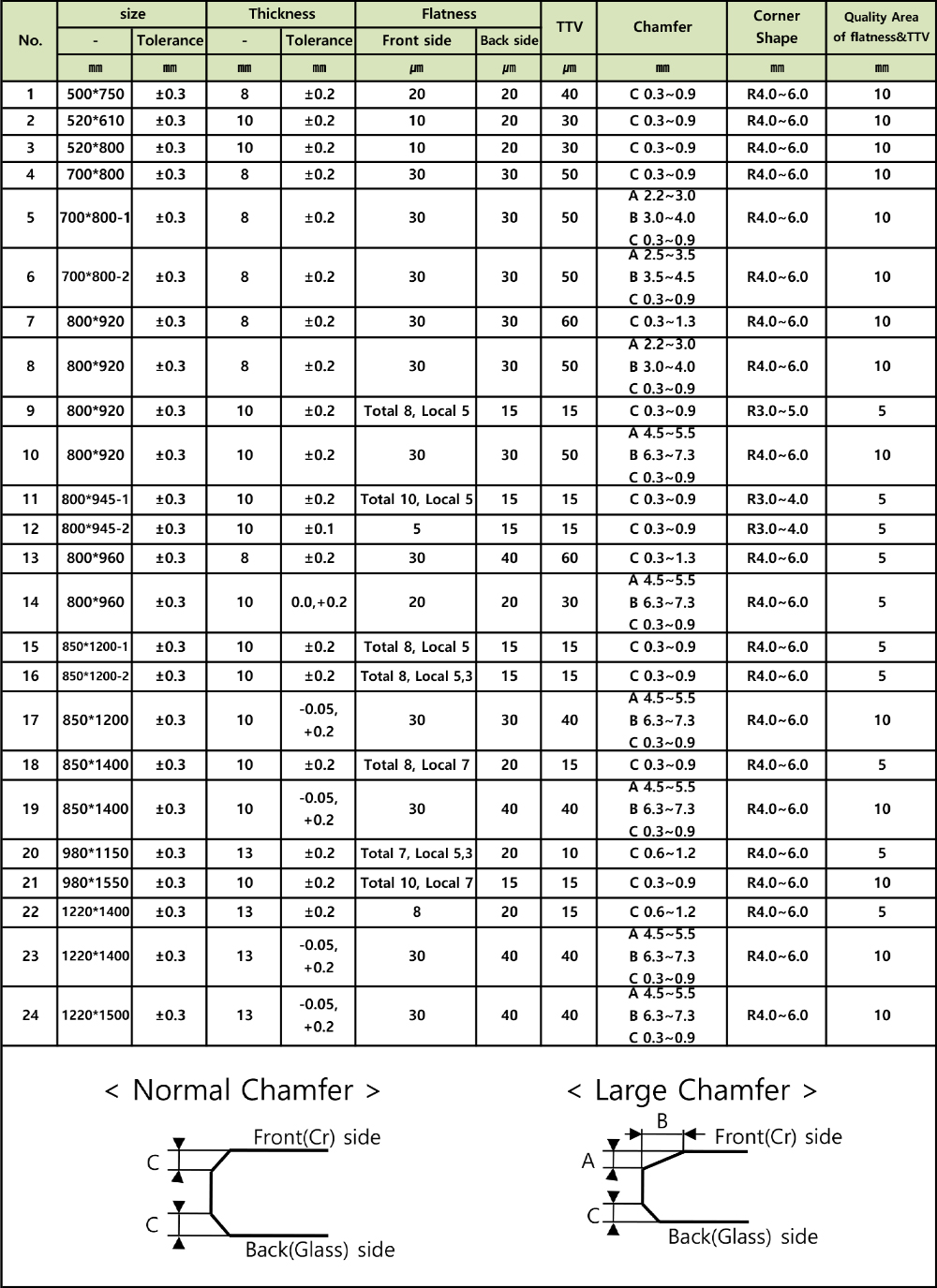

Business AreaPhoto Mask Product Line for Flat Panel Displays

- KTG researches, develops, manufactures, and sells quartz polishing, a core material for photo masks used in producing flat panel displays (FPD) such as LCDs and organic light-emitting diodes (OLEDs). In 2007, KTG began developing photo mask quartz polishing for LCDs by applying advanced photo mask quartz polishing technology. In recent years, with the advancement of 3D, 4K, 8K, touch panels, and smartphones, the quality of quartz polishing has been improving annually.

- KTG is engaged in the research, development, and manufacturing of quartz polishing, a core material for photo masks used to produce patterns for FPD panels, which are essential for the screens of large flat-panel TVs, computer monitors, and mobile phones. KTG holds a significant market share in the photo mask market for panels, with its expertise in large photo mask quartz polishing being a key area of technological competitiveness. The demand for FPD panels is driven by the increasing size of TVs in the past and, more recently, by the expansion into consumer electronics (TVs/monitors), mobile/IT devices (smartphones/tablets/laptops, watches/VR), and POLED (vehicle displays) applications.